Description

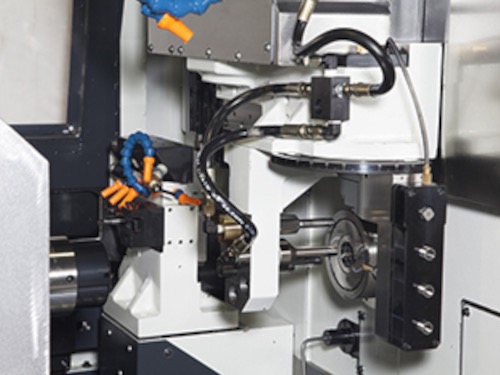

Designed with high efficiency and multi-tasking features, Jinn Fa JSL-42RB/42RBY/51RB/51RBY Swiss turning lathes integrate sliding head and sliding tool in one single machine. For applications in traveling-tool machining, these series are constructed around three axes (X, Y & Z) in combination with powered tool functions. It allows for turning, milling, drilling, and tapping operations with only one setup. The main spindle and sub-spindle perform machining synchronously, saving time for primary and secondary machining while ensuring higher accuracy for parts.

These series of Swiss turning lathe machines are suitable applicable parts machining for automotive and motorcycle parts, electronic parts, instrument parts, pneumatic and hydraulic parts, and medical instruments.

Feature

Specifications

| Item | Unit | JSL-32RB | JSL-32RBY | JSL-42RB | JSL-42RBY | JSL-51RB | JSL-51RBY |

| Max. turning diameter of main spindle |

mm | 32 | 32 | 42 | 42 | 51 | 51 |

| Max. turning diameter of sub-spindle | mm | 32 | 32 | 42 | 42 | 51 | 51 |

| Max. turning length(rotating guide bushing) | mm | 300 | 300 | 300 | 300 | 300 | 300 |

| Max. turning length(non-guide bushing) | mm | 130 | 130 | 130 | 130 | 130 | 130 |

| Max. drilling/tapping capacity of sub spindle | mm | Ø13 / M10 | Ø13 / M10 | Ø13 / M10 | Ø13 / M10 | Ø16 / M12 | Ø16 / M12 |

| Max. drilling/tapping capacity of main spindle | mm | Ø10/M8 | Ø10/M8 | Ø10/M8 | Ø10/M8 | Ø26 / M16 | Ø26 / M16 |

| Max. cross drilling/tapping capacity | mm | Ø10 / M6 | Ø10 / M6 | Ø10 / M6 | Ø10 / M6 | Ø12 / M10 | Ø12 / M10 |

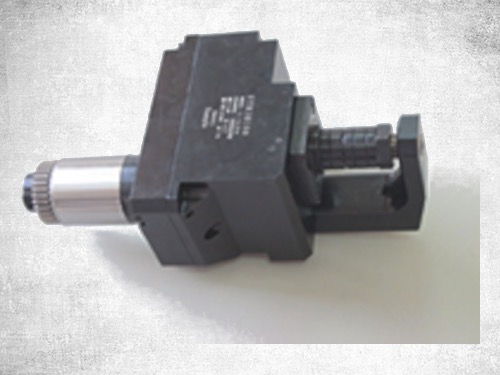

| O.D. tool holder | pcs | 6 (口16mm) / 5 (口20mm) | 6 (口16mm) / 5 (口20mm) | 6 (口16mm) / 5 (口20mm) | 6 (口16mm) / 5 (口20mm) | 6 (口16mm) / 5 (口20mm) | 6 (口16mm) / 5 (口20mm) |

| I.D. tool holder | pcs | 5 / Ø25mm | 5 / Ø25mm | 5 / Ø25mm | 5 / Ø25mm | 5 / Ø25mm | 5 / Ø25mm |

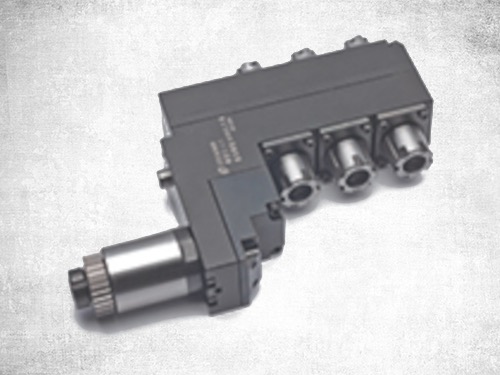

| S1 cross live tool holder | pcs | 6 (ER-20) | 6 (ER-20) | 6 (ER-20) | 6 (ER-20) | 6 (ER-20) | 6 (ER-20) |

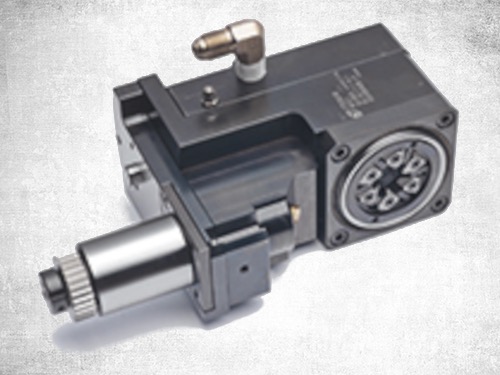

| Face drills of sub-spindle | pcs | 4 | 8 | 4 | 8 | 4 | 8 |

| Controlled axes (Incl. C-axis) | pcs | 7 | 8 | 7 | 8 | 7 | 8 |

| Main/sub-spindle bore | mm | Ø34 | Ø34 | Ø44 | Ø44 | Ø52 | Ø52 |

| Max. speed of main/sub-spindle | rpm | 7000 | 7000 | 6000 | 6000 | 4500 | 4500 |

| X1/Z1/Y1/X2/Z2/Y2 axis rapid traverse | m/min | 24 | 24 | 24 | 24 | 24 | 24 |

| Max. speed of S1 cross drilling | rpm | 4000 | 4000 | 4000 | 4000 | 4000 | 4000 |

| S1cross tooling drive motor | KW | 1.6 | 1.6 | 1.6 | 1.6 | 2.5 | 2.5 |

| S2 face tooling drive motor | KW | 0.75 | 0.75 | 0.75 | 0.75 | 2.5 | 2.5 |

| Max. speed of S2 drill | rpm | 4000 | 4000 | 4000 | 4000 | 4000 | 4000 |

| Main spindle motor | KW | 5.5 / 7.5 | 5.5 / 7.5 | 5.5 / 7.5 | 5.5 / 7.5 | 11 | 15 |

| Sub spindle motor | KW | 5.5 / 7.5 | 5.5 / 7.5 | 5.5 / 7.5 | 5.5 / 7.5 | 7.5 | 11 |

| X1/Z1 axis motor | KW | 1.4 | 1.4 | 1.4 | 1.4 | 2.5 | 2.5 |

| Y1/X2/Z2 axis motor | KW | 0.75 | 0.75 | 0.75 | 0.75 | 2.5 | 2.5 |

| Y2 axis motor | KW | non | 0.75 | non | 0.75 | non | 0.75 |

| Coolant pump motor | KW | 1.29 | 1.29 | 1.29 | 1.29 | 0.54 | 0.54 |

| Power required | KVA | 30 | 30 | 30 | 30 | 30 | 30 |

| Lubrication oil capacity | L | 2 | 2 | 2 | 2 | 2 | 2 |

| Coolant tank capacity | L | 250(100%) | 250(100%) | 250(100%) | 250(100%) | 250(100%) | 250(100%) |

| Machine dimensions(L x W x H) | mm | 3173x1695x2146 | 3173x1695x2146 | 3173x1695x2146 | 3173x1695x2146 | 3173x1695x2146 | 3173x1695x2146 |

| Weight | KG | 4900 | 4920 | 4900 | 4920 | 5450 | 5480 |

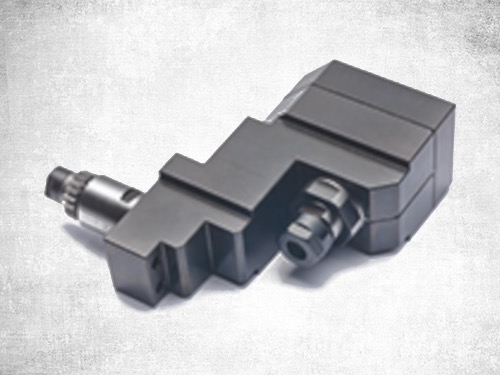

Tools

Main Spindle

Sub Spindle