Application

JINN FA - Taiwan CNC Lathes Machines and CNC Machining Centers Manufacturers, Suppliers.

Contact us now for your CNC lathe solutions!

Aerospace Industry

Aerospace Industry Applications – Precision Engineering for the Skies

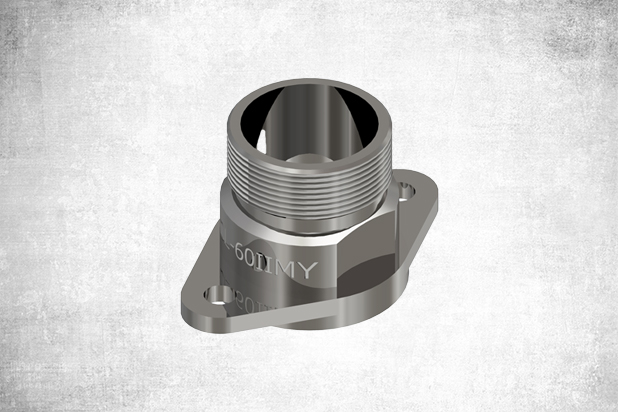

The aerospace industry demands uncompromising precision, performance, and reliability. Every component - from turbine shafts to satellite structures - must endure extreme temperatures, vibration, and stress while maintaining flawless dimensional stability. In this field, CNC turning and multi-axis machining are critical to ensuring both accuracy and efficiency.

With over four decades of experience in precision machine tool design and manufacturing, JINN FA Machine provides advanced CNC lathes and Swiss-type sliding head lathes engineered to meet the stringent requirements of aerospace part production. Our sliding head lathes empower manufacturers to achieve consistent quality, tighter tolerances, and higher throughput for today’s most demanding aerospace applications.

Aerospace Machining Challenges and Requirements

Aerospace manufacturing presents unique technical challenges:

- Extreme Precision and Tight Tolerances - Components must meet micron-level accuracy and maintain consistency over long production runs to ensure safety and reliability.

- Complex Geometries - Aerospace parts such as turbine blades, shafts, and housings often require multi-surface machining, angled holes, and intricate internal features.

- Difficult-to-Machine Materials - Titanium alloys, Inconel, and high-strength steels require exceptional spindle rigidity, stable structure, and high torque.

- Long Cycle Times and Multi-Operation Processes - Efficiency depends on minimizing setup changes and completing multiple operations in a single setup.

- Certification and Traceability - Aerospace manufacturers must comply with strict global standards such as AS9100, requiring stable process control and repeatable performance.

These challenges make machine rigidity, multi-axis capability, and thermal stability crucial in modern aerospace machining.

JINN FA Solutions for Aerospace Manufacturing

JINN FA Machine offers a comprehensive range of CNC turning solutions specifically designed for aerospace production needs. Our cnc sliding head machines are built to deliver superior stability, accuracy, and productivity - even when cutting high-strength materials or complex components.

- High Rigidity, Stable Machining: JINN FA’s Swiss-type sliding head lathes and fixed-head CNC turning centers are designed with reinforced bed structures and precision spindles to minimize vibration and ensure reliable accuracy.

- Multi-Axis Capability: With main/sub spindles, Y-axis control, and live tooling options, our CNC lathes allow complex part machining in a single setup - reducing cycle time and improving process stability.

- Precision Quality Control: Every JINN FA machine undergoes rigorous testing and inspection to meet international quality and performance standards.

- Tailored Support and Engineering Expertise: Our team provides full technical consultation, model selection, and customized configurations to match your production goals.

Recommended Machines for Aerospace Applications

Each model integrates advanced motion control and durable mechanical design, ensuring consistent accuracy for both prototype and mass production environments.

When precision, reliability, and long-term performance matter most, JINN FA Machine stands ready to support your aerospace manufacturing goals.

Backed by decades of engineering expertise and a deep understanding of aerospace machining requirements, we provide end-to-end solutions - from process consultation and trial cutting to machine installation and technical training. Let JINN FA Machine be your trusted partner in achieving excellence in aerospace component manufacturing.