Description

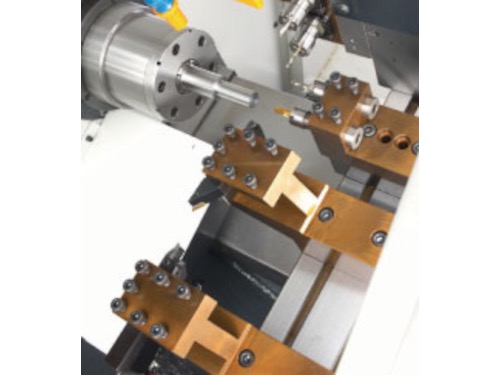

JINN FA Gang Tool CNC Lathe's Advantage:

1: Simplicity and Affordability

Gang tool lathes are often more cost-effective than turret lathes due to the simplicity of their tool change process. The lathe's standard axis servos and leadscrews handle all the work, whereas motorizing a turret can increase costs significantly.

2: Precision

Gang tool CNC lathes have an accuracy advantage over turret lathes due to their simpler moving parts, which reduces tolerance stack up and other types of slop. Additionally, the gang lathe is better suited for moving parts across shorter distances.

3: Rapidity

The tool change process in gang lathes is incredibly speedy as it utilizes slide motion for tool changes, eliminating the need for turret indexing.

4: Quick Installation

Gang tooling lathes offer fast setup times, with a simple set of tools and the ability to switch out a single block for a specific size twist drill allowing for a wide range of gang work to be accomplished.

5: Durability

Gang Tool lathes are known for their robustness, which is directly linked to their simplicity. With fewer moving parts, gang lathes are less prone to errors and malfunctions.

Features

Specifications

| Item | Unit | SMART-42 |

SMART-42T8

|

| Max. swing over bed |

mm | 320 |

320 |

| Max. turning diameter |

mm | Ø200 |

Ø200 |

| Max. turning length |

mm | 117 |

140 |

| Max. bar capacity |

mm | Ø 42 |

Ø 42 |

| Bore of spindle |

mm | Ø 44 |

Ø 44 |

| Spindle bearing inside dia. |

mm | Ø 80 |

Ø 80 |

| Spindle nose |

mm | A2-5 |

A2-5 |

| Spindle speed range |

rpm |

45 ~ 3500 |

45 ~ 3500 |

| Spindle motor |

kw | 5.5 |

5.5 |

| Max. travel X1 / Z1 axis |

mm | 215 / 127 |

215 / 150 |

| Rapid traverse X1 / Z1 axis |

mm | 16 | 16 |

| Turret indexing time |

sec | - | 0.3 |

| Machine slant degree |

20° |

20° | |

| Slide way type |

|

Square Guide way |

Square Guide way |

| 3-jaw chuck size |

|

6” |

6” |

| Collet type |

mm |

173E |

173E |

| Turning tool size | mm | □20 | □20 |

| Boring tool diameter |

mm | Ø 25 |

Ø 25 |

| Cutting tool size |

mm |

□20 |

□20 |

| X / Z axis ball screw dia. |

mm |

Ø 32 |

Ø 32 |

| X / Z axis feeding motor |

kw |

0.75 / 1.0 |

0.75 / 1.0 |

| Hydraulic motor |

kw |

0.75 | 0.75 |

| Lubrication motor |

w | 150 |

150 |

| Power requirement |

kva | 10 | 10 |

| Coolant tank capacity |

L | 80 | 80 |

| Machine dimensions (LxWxH) |

mm | 2813x1350x1825 |

2813x1350x1825 |

| Weight |

kg | 2200 | 2200 |