Description

The JINN FA MACHINE company's JSL-20RB and JSL-20RBY Swiss-type CNC sliding head lathes are premium solutions tailored to meet the diverse needs of modern manufacturing industries. Engineered for maximum operational flexibility, these advanced machines are ideal for producing automotive and motorcycle parts, electronic components, precision instruments, and pneumatic and hydraulic parts. Their high precision and efficiency make them particularly well-suited for these sectors. The JSL-20RBY features a sub-spindle tooling system, while both models boast comprehensive main spindle and tooling systems, enabling them to handle a variety of intricate machining tasks with ease.

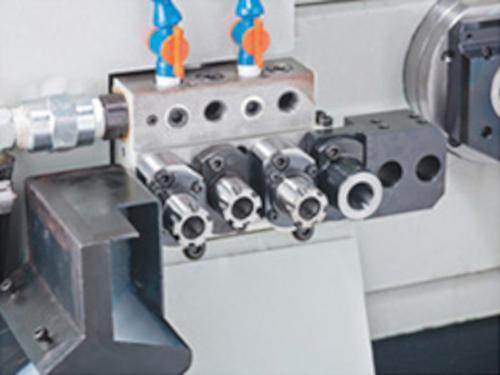

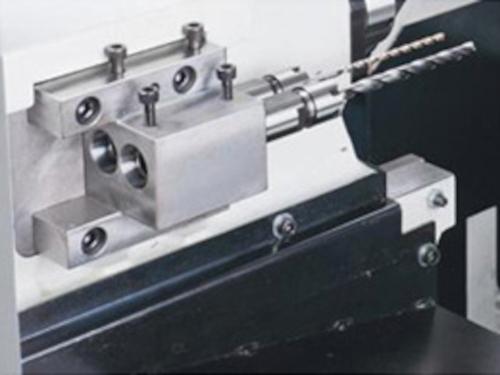

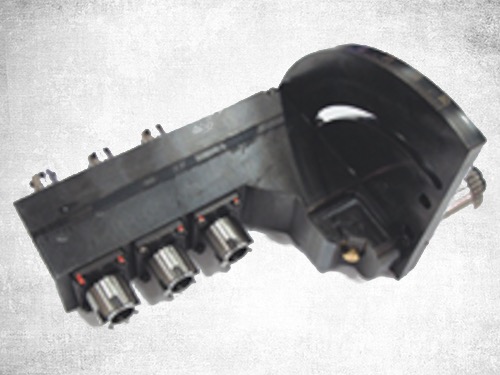

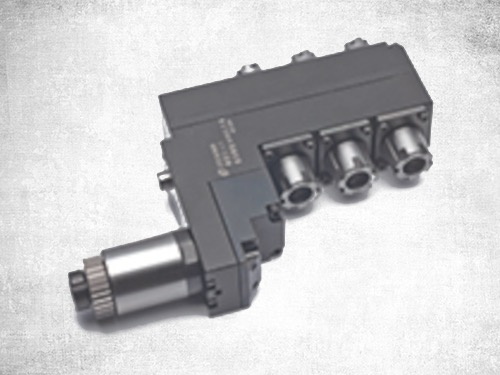

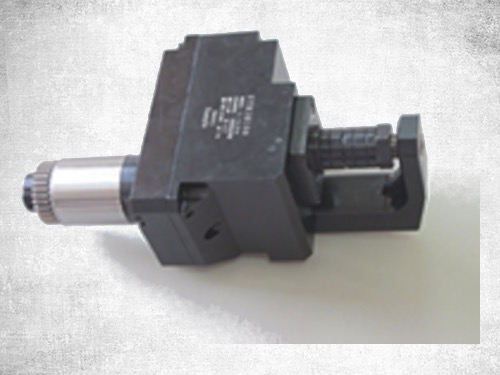

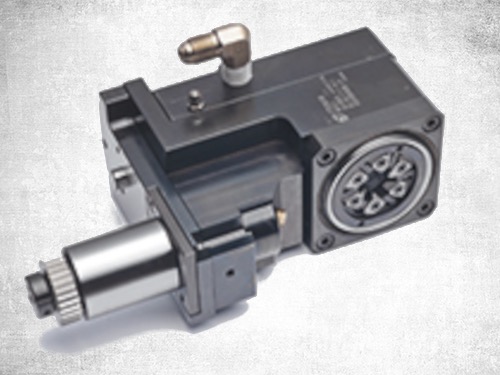

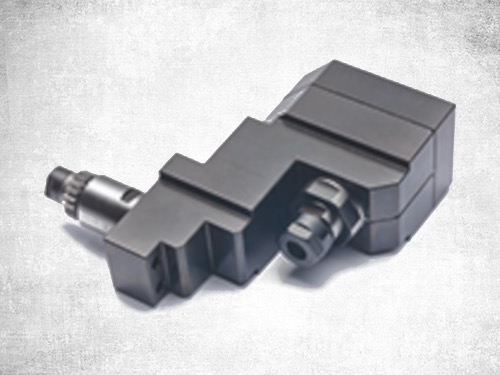

One of the standout features of the JSL-20RB and JSL-20RBY models CNC sliding head machines is their remarkable versatility. Despite their compact construction, these machines are equipped with a sub-spindle that allows for simultaneous turning, milling, drilling, and tapping. This synchronous operation between the main spindle and sub-spindle not only enhances machining efficiency but also significantly reduces secondary processing time. Additionally, the option to convert side drilling to end drilling upon request further increases operational adaptability.

The JSL-20RB model features C1/Z1/X1/Y1/C2/Z2/X2 axis controls, while the JSL-20RBY model adds an additional Y2 axis for even greater control and precision. Both models support a wide range of optional accessories to further enhance their functionality, including devices for deep hole drilling, polygon forming, and power-driven saw units.

For businesses looking to optimize their production processes with state-of-the-art CNC sliding head machines, the JINN FA JSL-20RB and JSL-20RBY offer unparalleled performance and reliability. Contact us now to learn more about how these machines can meet your specific manufacturing needs.

Feature

Specifications

| Item | Unit | JSL-20RB | JSL-20RBY |

| Main Spindle Max. Turning Diameter |

mm | 20 | 20 |

| Sub Spindle Max. Turning Diameter | mm | 20 | 20 |

| Max. Turning Length (rotating bush) | mm | 250/190 | 250/190 |

| Max. Turning Length (non bush) | mm | Non/50 | Non/50 |

| Max. Turning Length (fixed bush) | mm | 280/220 | 280/220 |

| Main Spindle Max. Drilling/Tapping Capacity | mm | Ø10/M8 | Ø10/M8 |

| Max. Cross Drilling/Tapping Capacity | mm | Ø8/M6 | Ø8/M6 |

| OD Tool Holder | pcs | 6/□12mm | 6/□12mm |

| ID Tool Holder | pcs | 4/Ø22mm | 4/Ø22mm |

| S1 Cross Live Tool Holder | pcs | 5/ER-16 | 5/ER-16 |

| Sub Spindle Face Tool Holder | pcs | 4 | 8 |

| Control Axis (with C axis) | pcs | 7 | 8 |

| Main/Sub Spindle Bore | mm | Ø26.6 | Ø26.6 |

| Main/Sub Spindle Max. Speed | rpm | 10000/8000 | 10000/8000 |

| X1/Z1/Y1/X2/Z2/Y2 Rapid Traverse | m/min | 24 | 24 |

| S1 Cross Drilling Max. Speed | rpm | 8000 | 8000 |

| S1 Cross Driven Motor | kw | 1.2 | 1.2 |

| S2 Face Driven Motor | kw | 0.5 | 0.75 |

| S2 Face Drilling Max. Speed | rpm | 8000 | 8000 |

| Main Spindle Motor | kw | 2.2/3.7 | 2.2/3.7 |

| Sub Spindle Motor | kw | 2.2/3.7 | 2.2/3.7 |

| X1/Z1/Y1 Motor | kw | 0.75 | 0.75 |

| X2/Z2 Motor | kw | 0.5 | 0.5 |

| Y2 Motor | kw | Non | 0.5 |

| Coolant Pump | kw | 2.3 | 2.3 |

| Power Requirements | kw | 20KVA | 20KVA |

| Lubrication Capacity | L | 2 | 2 |

| Coolant Tank Capacity | L | 220(100%) | 220(100%) |

| Machine Dimensions (LxWxH) | mm | 2846x1284x2024 | 2846x1284x2024 |

| Weight | kg | 2670 | 2700 |

Tools

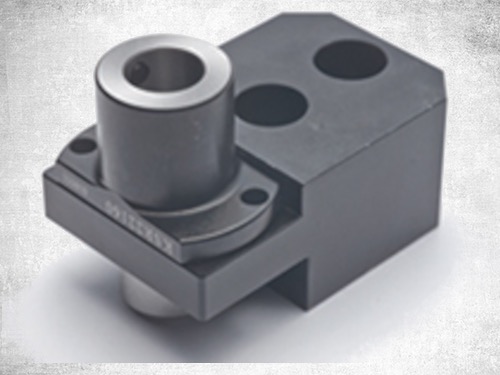

Main Spindle

Sub Spindle