JCL : Fixed head horizontal CNC lathe

JCL-42TS/52TS/60TS/42TSM/52TSM/60TSM

Superior Performances of Efficiency and Convenience Priemier Solution for Production Enhancement.

- The sub-spindle is suitable for back side machining which saves time in secondary machining.

- The sub-spindle accommodates a 6" 3-jaw chuck or a collet chuck.

- The two-spindle series feature high spindle speed, fine precision and excellent efficiency.

- 12-position turret.

- Features

- Specifications

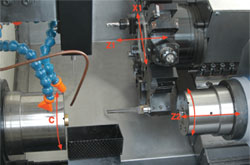

SUB-SPINDLE JCL-52/60TS, 52/60TSM

- The sub-spindle can be mounted with a 6" 3-jaw chuck or a collet chuck, It is driven by a 5.5KW motor.

POWER TURRET

- The power turret features bi-directional tool change. Tool change time between adjacent tools is only 0.2 seconds. The turret loading capacity is 12 tools. The rotary power tool holder can be fitted with 6 tools.

MAIN SPINDLE, SUB-SPINDLE AND PARTS CATCHER

- The combination of the main and sub-spindle allows the machine to perform front and back side machining on a workpiece at one time.

- When requested, a parts catcher is available. It provides convenient and efficient parts collection.

HEAT EXCHANGER FOR ELECTRICAL CABINET

- The high efficiency heat exchanger allows for constant temperature in the electrical cabinet. It also ensures the performance dependability of electronic components.

RIGID, PRECISE SPINDLE

- The spindle is precision machined from Chrome-molybdenum alloy stee, hardened and dynamically balanced to assure lifetime accuracy.

- The spindle is supported by class P4 angular contact ball bearings, featuring outstanding axial and radial loading capabilities. Maximum stability of spindle is enhanced especially when performing heavy cutting.

HYDRAULIC POWER UNIT

- The hydraulic power unit provides power for 3-jaw chuck, hydraulic turret and hydraulic tailstock.

- The hydraulic power unit consists of high quality components, assuring extremely stable motions, low noise and long service life.

Copyright © JINN FA MACHINE Design by Taiwan Products, B2BChinaSources, B2BManufactures